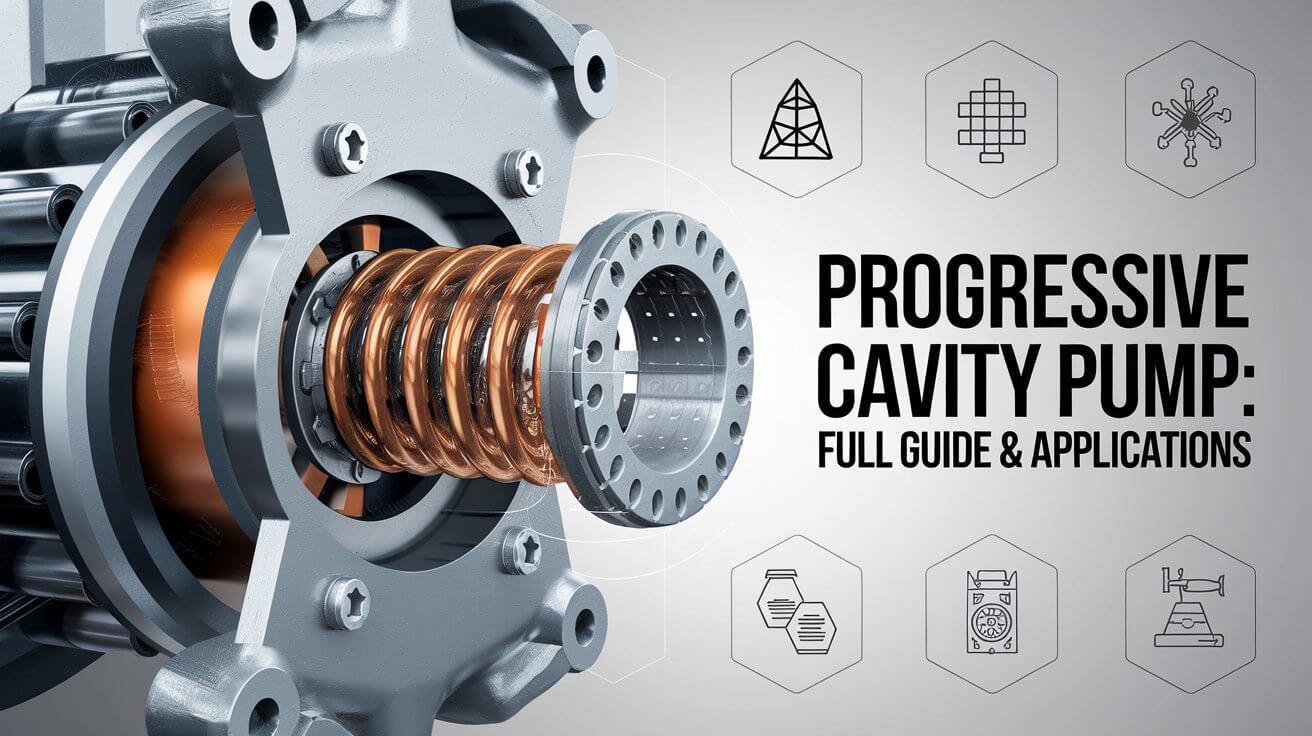

What is a Progressive Cavity Pump? Full Guide & Applications

A progressive cavity pump, also known as a progressing cavity pump, eccentric screw pump, or mono pump, is a type of positive displacement pump designed to handle highly viscous, abrasive, and multiphase fluids. Its unique construction features a helical rotor and stator mechanism that creates cavities to move fluid steadily through the pump. This type of pump is highly effective in industries like wastewater treatment, oil and gas, food processing, and pharmaceuticals, where consistent flow rates and the ability to handle complex fluids are critical.

Progressive cavity pumps stand out because they can handle a wide range of fluid types, from low-viscosity liquids to thick slurries. Their ability to maintain consistent pressure and flow, regardless of the fluid type, makes them versatile across numerous applications. In this article, we’ll delve into the working principles, components, applications, advantages, and much more regarding progressive cavity pumps.

How Does a Progressive Cavity Pump Work?

Basic Working Principle

At the core of a progressive cavity pump’s operation is the interaction between a helical rotor and an elastomeric stator. The rotor, often metallic and shaped like a screw or helix, rotates inside the stator, which is a cylindrical, rubber-like sleeve. As the rotor turns, cavities (spaces between the rotor and stator) are formed. These cavities move fluid along the pump as they progress from the suction side to the discharge side.

What makes this design so effective is the constant volume of these cavities, ensuring a steady and non-pulsating flow of fluid. As the rotor moves eccentrically, the fluid is progressively pushed forward through the pump, which is where the term “progressive cavity” comes from. This allows the pump to maintain a smooth flow even when dealing with viscous or slurry-like fluids.

Positive Displacement Mechanism

Progressive cavity pumps belong to the positive displacement category. Positive displacement pumps work by trapping a fixed volume of fluid and forcing it into the discharge pipe. In the case of progressive cavity pumps, the trapped fluid is moved through the pump as the cavities between the rotor and stator advance, ensuring consistent fluid transfer. This differs from centrifugal pumps, which rely on high-speed rotation to create pressure and are better suited for low-viscosity fluids like water.

Flow Characteristics

The flow rate of a progressive cavity pump is directly proportional to the rotor’s speed. This linear relationship allows for precise control of the flow, making the pump an ideal choice for applications that require accurate dosing or metering of fluids. The pump can handle high-pressure conditions and transfer fluids over long distances, even when the fluids are thick or contain solid particles.

Components of a Progressive Cavity Pump

Rotor

The rotor is a key component of a progressive cavity pump. It’s usually metallic and shaped like a corkscrew or helix. The rotor’s surface can be coated with wear-resistant materials like chrome or stainless steel, depending on the application. The quality and durability of the rotor directly affect the pump’s performance, especially when handling abrasive or corrosive fluids.

Stator

The stator is the cylindrical sleeve that houses the rotor. It is typically made from an elastomer (rubber-like material) and is custom-molded to fit the specific application. The stator’s main function is to create a seal around the rotor, ensuring that fluid does not leak or bypass the cavities. One of the critical aspects of the stator is its sensitivity to dry running. If the pump operates without fluid, the stator can overheat and become damaged, which can lead to operational issues.

Drive Shaft and Universal Joints

The drive shaft transfers the rotational energy from the motor to the rotor. To accommodate the eccentric motion of the rotor, the pump utilizes universal joints that allow for smooth and flexible movement. These joints must be well-lubricated and maintained to ensure the longevity of the pump and prevent mechanical failures.

Seals and Bearings

Seals are essential in progressive cavity pumps to prevent fluid leakage and maintain pressure. Given the high pressure and abrasive nature of the fluids often handled by these pumps, the seals must be durable and capable of withstanding significant wear and tear. Bearings support the pump’s rotating components and ensure smooth operation, even under heavy loads.

Applications of Progressive Cavity Pumps

Industrial Uses

One of the most common applications of progressive cavity pumps is in the wastewater treatment industry. These pumps are used to handle sludge, slurry, and other viscous or abrasive fluids that are commonly found in water treatment plants. Their ability to handle solids and maintain consistent flow rates makes them ideal for this environment.

In the oil and gas industry, progressive cavity pumps are used for transporting multiphase fluids, which may contain both liquids and gases, as well as crude oil. These pumps are well-suited for moving fluids over long distances and through pipelines under high pressure.

In the food and beverage industry, progressive cavity pumps are used to move thick fluids like dough, fruit mixtures, and pastes. These pumps can maintain hygiene standards required in food production while handling challenging substances without damaging them.

Dosing and Metering

Progressive cavity pumps are also commonly used in dosing and metering applications. In industries such as pharmaceuticals and cosmetics, accurate dosing of chemicals or other additives is crucial. The pump’s ability to deliver precise, repeatable volumes makes it an excellent choice for these tasks.

Hygienic Applications

In addition to their industrial uses, progressive cavity pumps are often used in hygienic applications where sanitation is critical. These pumps are designed with materials that comply with hygienic standards, making them suitable for use in the production of food, beverages, and pharmaceuticals.

Other Industries

Beyond wastewater treatment and food processing, progressive cavity pumps are also found in industries like mining, agriculture, and chemical processing, where the ability to handle abrasive, viscous, or slurry-like fluids is essential.

Advantages of Using a Progressive Cavity Pump

Ability to Handle Viscous Fluids

One of the standout features of progressive cavity pumps is their ability to handle highly viscous fluids. Unlike centrifugal pumps, which struggle with thick fluids, progressive cavity pumps can move substances like slurry, mud, or even highly viscous chemicals with ease. This makes them highly versatile for industries where fluid viscosity is a challenge.

Smooth, Low Pulsation Flow

Progressive cavity pumps provide a smooth and consistent flow with minimal pulsation. This is crucial in applications that require steady pressure and fluid movement, such as in chemical dosing or food production. The low pulsation also reduces the wear on the pump and the associated piping, prolonging the system’s overall life.

Versatility

Another advantage of progressive cavity pumps is their versatility. They can handle a wide range of fluids, from thin liquids to highly viscous slurries. Moreover, they can manage fluids containing solids, making them a good choice for applications where the fluid may not be homogeneous, such as in wastewater treatment.

High-Pressure Capability

Progressive cavity pumps are known for their ability to handle high-pressure applications. This is particularly useful when fluids need to be transported over long distances or when the system must overcome significant resistance, such as in oil pipelines or slurry transfer in mining operations. These pumps can achieve pressures of up to 48 bar, depending on the design and number of stages.

Disadvantages and Challenges

Wear and Tear

While progressive cavity pumps are highly durable, they can suffer from wear and tear, especially when handling abrasive fluids. The rotor and stator can wear down over time, particularly if the fluid contains sharp particles. Regular maintenance and material upgrades can help mitigate these issues, but this is still a challenge for some applications.

Sensitivity to Dry Running

One of the major drawbacks of progressive cavity pumps is their sensitivity to dry running. If the pump operates without fluid, the friction between the rotor and stator can cause overheating, leading to permanent damage. To prevent this, many systems include sensors or protective devices that shut the pump down if dry running is detected.

Maintenance Needs

Due to the complexity of the pump’s design, regular maintenance is required to keep it running efficiently. Components like seals, joints, and bearings need to be inspected and lubricated regularly. While this maintenance ensures the pump’s longevity, it also adds to the overall operational costs.

Types of Progressive Cavity Pumps

Single vs. Multi-Stage Designs

Progressive cavity pumps come in both single-stage and multi-stage designs. The number of stages determines the pressure the pump can generate. Single-stage pumps are typically used for low-pressure applications, while multi-stage pumps are used for high-pressure tasks. Each additional stage allows the pump to handle a higher head pressure.

Specialized PC Pumps

In addition to the basic single- and multi-stage designs, there are specialized progressive cavity pumps that are designed for specific applications. For example, some pumps come equipped with screw feeders or paddles to help break up solids before they enter the pump, making them ideal for slurry or other solid-laden fluids.

Hygienic and Dosing Pumps

For industries like pharmaceuticals and food processing, there are hygienic versions of progressive cavity pumps that are designed to meet strict sanitation standards. These pumps often feature materials that are resistant to bacterial growth and are easy to clean. There are also specialized dosing pumps that are designed for accurate metering of chemicals or additives.

Design Considerations for Progressive Cavity Pumps

Material Choices

When selecting a progressive cavity pump, it’s important to consider the materials used for the rotor and stator. For applications involving abrasive or corrosive fluids, it may be necessary to choose more durable materials like stainless steel or specialized elastomers. The material selection will directly affect the pump’s performance and lifespan.

Size and Capacity

The size of the pump must be matched to the application’s flow rate, viscosity, and pressure requirements. A pump that’s too small may struggle to move the fluid efficiently, while an oversized pump may lead to higher operationaltoo large may cause inefficiencies in terms of energy consumption and cost.

Customization Options

Progressive cavity pumps offer a range of customization options, allowing for precise adaptation to various industrial needs. These include different inlet types, such as hoppers for handling viscous slurries, or mechanical seals for applications where fluid leakage must be minimized. Rotor and stator pitches can also be adjusted to optimize the pump’s performance for specific tasks.

Common Issues and Troubleshooting

Dry Running and Overheating

One of the most common problems with progressive cavity pumps is dry running, which can cause the stator to overheat and degrade. To prevent this, modern pumps often include sensors that detect a lack of fluid and shut the pump down before damage occurs. Regularly checking fluid levels and ensuring that the pump operates within its designed capacity will also help avoid dry running.

Leaks and Seal Failures

Leaks in progressive cavity pumps are usually caused by seal failures. Over time, seals wear down due to the high pressures and abrasive fluids that these pumps handle. Regular inspection and replacement of seals can prevent leaks from occurring. It’s also important to ensure that the seals are appropriate for the fluid being pumped, as some materials may degrade more quickly when exposed to certain chemicals.

Decreased Efficiency

If a progressive cavity pump begins to lose efficiency, it’s often due to wear on the rotor or stator. As these components degrade, the cavities between them become less effective at moving fluid. Replacing worn parts or upgrading to more durable materials can help restore the pump’s efficiency.

Progressive Cavity Pumps vs. Other Pump Types

PC Pumps vs. Centrifugal Pumps

While both progressive cavity pumps and centrifugal pumps are used to move fluids, their mechanisms and ideal applications are quite different. Centrifugal pumps rely on high-speed rotation to create pressure, making them better suited for low-viscosity fluids like water. In contrast, progressive cavity pumps are ideal for highly viscous or abrasive fluids, as they can maintain a consistent flow regardless of the fluid’s properties.

PC Pumps vs. Peristaltic Pumps

Peristaltic pumps and progressive cavity pumps are both positive displacement pumps, but they differ in how they move fluid. Peristaltic pumps use rollers to squeeze a flexible tube, while progressive cavity pumps rely on the interaction between the rotor and stator to create cavities. Progressive cavity pumps are generally better suited for handling highly viscous or solid-laden fluids, while peristaltic pumps are often used for more delicate or shear-sensitive fluids.

PC Pumps vs. Gear and Vane Pumps

Gear and vane pumps are also positive displacement pumps, but they work by trapping fluid between gears or vanes. While these pumps are effective at handling moderate pressures and viscosities, they can struggle with highly abrasive fluids. Progressive cavity pumps are typically a better choice for applications involving slurry or thick liquids, as they can handle solid particles without suffering excessive wear.

Selecting the Right Progressive Cavity Pump for Your Application

Key Considerations

When selecting a progressive cavity pump, there are several key factors to consider. First, you’ll need to assess the fluid’s viscosity, solids content, and chemical properties. This will help you determine the appropriate rotor and stator materials. You’ll also need to consider the required flow rate and pressure, as these will influence the size and number of stages in the pump.

Environmental and Operational Factors

The operating environment can have a significant impact on the pump’s performance. For example, high temperatures or aggressive chemicals can degrade the elastomers used in the stator. It’s important to select materials that are resistant to the specific conditions of your application. You’ll also need to consider the availability of maintenance and spare parts, especially if the pump will be used in a remote or challenging environment.

Cost vs. Efficiency

While progressive cavity pumps can be more expensive upfront than other types of pumps, their ability to handle challenging fluids and maintain consistent flow rates often makes them more cost-effective in the long run. It’s important to balance the initial cost of the pump with its expected lifespan and maintenance needs.

Innovations in Progressive Cavity Pump Technology

Modern Coatings and Materials

Recent advancements in material science have led to the development of more durable coatings for progressive cavity pumps. These coatings can increase the lifespan of the rotor and stator, especially when handling abrasive or corrosive fluids. For example, some pumps now use advanced ceramic coatings that are highly resistant to wear and corrosion.

Automation and Sensors

The integration of automation and sensors has made progressive cavity pumps more efficient and reliable. Sensors can monitor the pump’s performance in real-time, detecting issues like dry running or overheating before they lead to damage. Automated control systems can also adjust the pump’s speed and flow rate based on the fluid’s viscosity, ensuring optimal performance at all times.

Energy Efficiency Improvements

As industries strive to reduce energy consumption, progressive cavity pumps have benefited from advancements in motor and drive design. Modern pumps are equipped with energy-efficient motors that use less power while maintaining the same level of performance. Additionally, variable speed drives allow for precise control over the pump’s output, reducing energy waste and lowering operational costs.

Conclusion: Why Choose a Progressive Cavity Pump?

Progressive cavity pumps offer numerous advantages for industries that need to handle viscous, abrasive, or multiphase fluids. Their unique design allows them to provide consistent, low-pulsation flow, even in challenging conditions. Whether you’re dealing with sludge in a wastewater treatment plant, transporting crude oil in a pipeline, or dosing chemicals in a pharmaceutical facility, progressive cavity pumps are versatile and reliable solutions.

With the ability to handle high pressures, deliver precise flow rates, and resist wear in harsh environments, progressive cavity pumps are a valuable investment for many applications. By selecting the right pump for your specific needs and ensuring proper maintenance, you can maximize the efficiency and longevity of your system.

In summary, if your operation requires a pump that can manage thick, abrasive, or solid-laden fluids, a progressive cavity pump is likely your best option. Its durability, versatility, and precision make it a standout choice across numerous industries, from oil and gas to food processing and beyond.