How to Tell If a Fuse Is Blown

A blown fuse can interrupt the flow of electricity, causing devices or systems to stop working, often without warning. Whether in cars, homes, or industrial equipment, knowing how to check if a fuse is blown can save time, prevent damage, and even reduce the risk of fire. In this guide, you’ll learn the common signs of a blown fuse, how to inspect one visually or with a multimeter, and essential steps to replace it. We’ll also dive into preventive tips to keep your fuses functioning optimally.

What Is a Fuse and Why Does It Blow?

Purpose of Fuses in Electrical Systems

Fuses are safety devices designed to prevent electrical overloads by breaking the flow of electricity when too much current flows through a circuit. When the current exceeds a certain level, the fuse “blows” by melting its internal wire, stopping the circuit to protect connected devices. Unlike circuit breakers, which can reset, fuses need to be replaced once blown.

How Fuses Operate and Common Types

Different types of fuses suit various applications:

- Cartridge Fuses: Common in home electrical systems, these cylindrical fuses are enclosed and require a fuse holder.

- Blade Fuses: Found in cars and other vehicles, these fuses are flat with two blade terminals.

- Glass Tube Fuses: Often used in electronic devices, these fuses are easy to inspect visually.

- Ceramic and Industrial Fuses: These high-amperage fuses are more durable, often designed to handle industrial machinery.

Main Causes of a Blown Fuse

Fuses typically blow due to:

- Overloaded Circuits: Drawing too much power on one circuit can cause a fuse to blow.

- Short Circuits: Faulty wiring or damaged insulation can redirect current, causing a fuse to overload.

- Ground Faults: If a live wire touches a ground surface, it can create an unexpected flow, tripping the fuse.

- Arc Faults: When electric sparks occur due to damaged wiring, this can lead to a blown fuse.

Understanding these causes can help in diagnosing fuse issues and preventing future blowouts.

Symptoms of a Blown Fuse in Different Scenarios

Signs of a Blown Fuse at Home

In household settings, a blown fuse might manifest as sudden power loss in an outlet, appliance, or entire room. You might also notice:

- A humming noise or faint burning smell near the fuse box

- Certain appliances or lights turning off while others remain on

- Visible signs of damage on the fuse itself

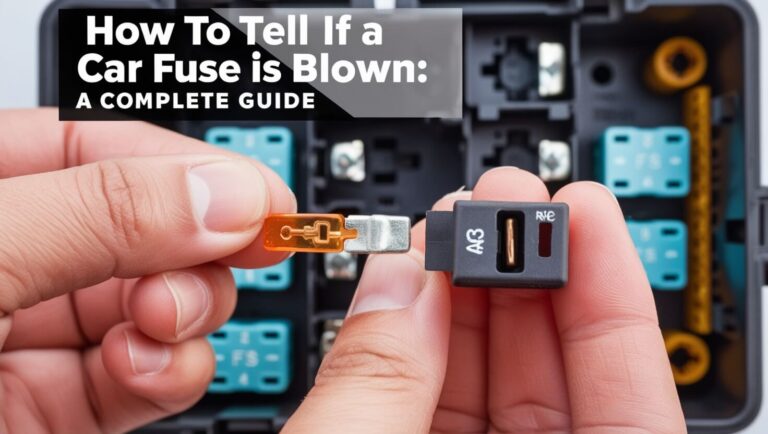

How to Tell If a Car Fuse Is Blown

In vehicles, blown fuses affect specific components, such as lights, radio, or air conditioning. The car may also display warning lights. To check:

- Inspect the fuse visually for a break or melted metal inside the fuse’s plastic casing.

- Dark marks or residue inside the fuse are signs that it has blown.

Industrial Fuse Blowing Symptoms

In industrial settings, blown fuses may cause machinery to stop suddenly, interrupting production. Higher-amperage fuses often require specialized testing equipment, like clamp meters, to check for functionality.

How to Visually Inspect a Fuse for Damage

Key Visual Cues of a Blown Fuse

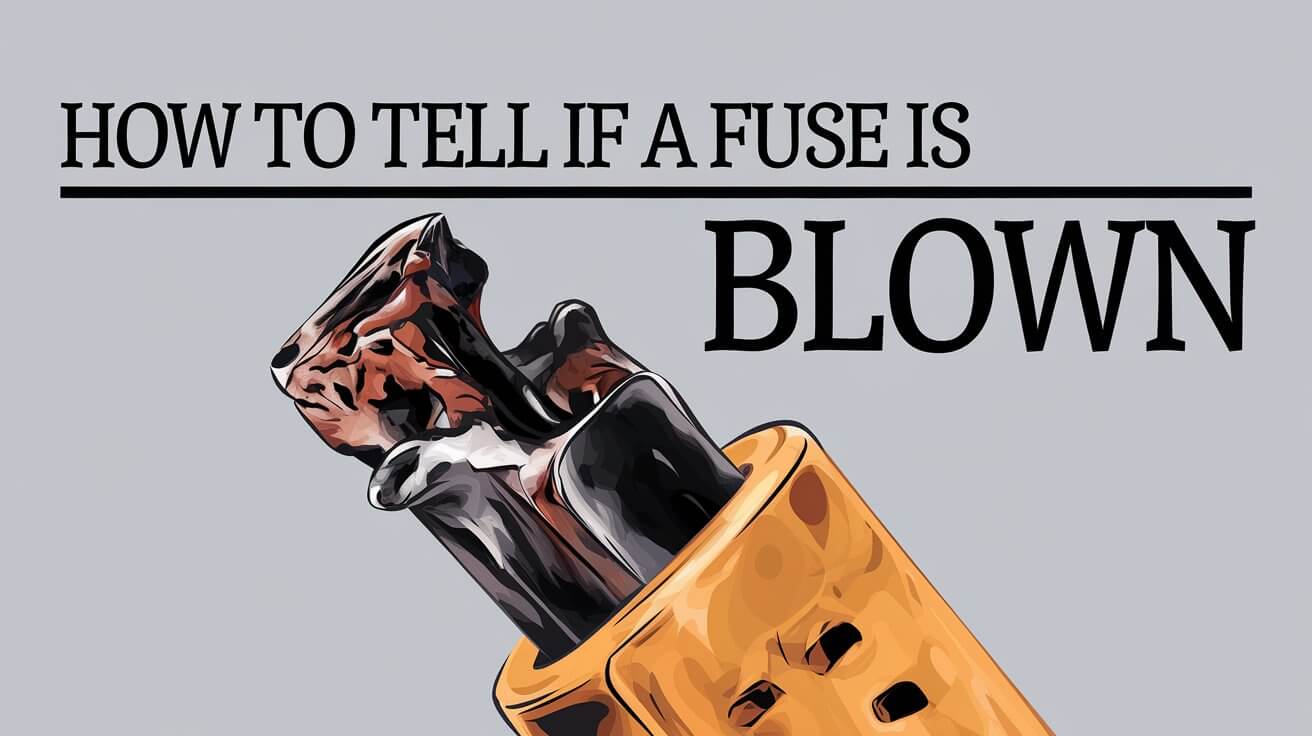

The first step in diagnosing a blown fuse is a visual inspection. Here’s what to look for:

- Dark Marks or Burn Residue: A burnt or melted appearance inside the fuse indicates a blowout.

- Broken Metal Strip: The fuse’s internal metal strip should be continuous. If broken, the fuse has likely blown.

- Distorted or Melted Plastic: Excessive heat can cause plastic fuses to warp or melt, indicating a blowout.

Using a Multimeter to Check Continuity

For more precise results, testing with a multimeter is ideal. Follow these steps:

- Set the multimeter to continuity mode.

- Place one probe on each end of the fuse.

- If the multimeter beeps, the fuse is intact. If there’s no beep or high resistance reading, the fuse is blown.

A multimeter reading of zero ohms indicates a good fuse, while a high or infinite reading indicates an open circuit (blown fuse).

Step-by-Step Guide: Diagnosing a Blown Fuse

Safety First: Preparation Before Testing

Before working on any fuse, prioritize safety:

- Disconnect power or, in cars, disconnect the battery to avoid accidental shocks.

- Wear gloves and protective eyewear when handling electrical equipment.

Checking Household Fuses

To inspect household fuses:

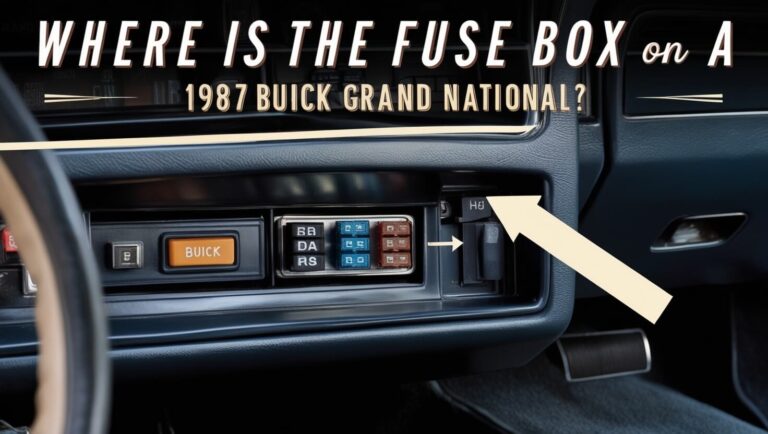

- Locate the fuse box, usually found in basements, garages, or utility rooms.

- Identify the fuse linked to the affected area or appliance.

- Perform a visual inspection or multimeter test to check for continuity.

Diagnosing Car Fuses

In cars, fuses are often found in two places: under the dashboard and in the engine bay.

- Use the car manual to locate the specific fuse related to the faulty component.

- Use a fuse puller to remove the fuse carefully.

- Check the fuse for any broken metal, dark marks, or signs of burning.

Testing Industrial Fuses

Industrial fuse testing may require specialized tools and extra caution:

- Turn off power to the machine.

- Use a clamp meter to check continuity for higher-amperage fuses.

- Replace blown fuses with ones rated specifically for industrial applications.

How to Replace a Blown Fuse Safely

Selecting the Correct Fuse Replacement

Choosing the right fuse replacement is critical:

- Match the amperage and type (e.g., 15A, 20A).

- Avoid higher or lower-rated fuses, as they can cause further damage or fail to protect the circuit.

Step-by-Step Fuse Replacement

- Remove the old fuse by gently pulling it from its slot.

- Insert a new fuse with the same amperage rating, ensuring it’s securely in place.

- Turn on power or reconnect the car battery and test if the circuit is functioning.

Common Mistakes When Diagnosing or Replacing Fuses

Misidentifying the Problem

Sometimes, the issue may not be with the fuse but rather with a faulty component. Ensure that a fuse is indeed the cause of the issue before replacing it.

Choosing Incorrect Fuse Ratings

Installing a fuse with a higher rating than recommended may cause circuit overheating, while a lower rating could lead to unnecessary blowouts.

Handling and Testing Precautions

Avoid directly touching metal contacts on fuses, as this can cause accidental shocks or shorts.

Preventing Future Fuse Blows

Regular Electrical Maintenance Tips

Routine checks on home wiring and vehicle systems can help prevent future issues. Replace old or corroded fuses regularly.

Avoiding Overloading Circuits

To avoid overloading, distribute high-power devices across different circuits. For example, plugging in a space heater and an air conditioner on the same circuit can lead to frequent blowouts.

Investing in Surge Protectors

Surge protectors help prevent electrical spikes from reaching your circuits, especially valuable for protecting electronic devices in homes and workplaces.

Conclusion

Identifying and replacing a blown fuse is a straightforward yet essential skill that can save time and prevent damage to electrical devices. With basic tools like a multimeter and a few safety precautions, you can diagnose and replace a fuse at home or in a vehicle. For persistent issues or frequent fuse blowouts, it’s best to consult a professional, as these can signal deeper electrical problems. Taking proactive steps, like avoiding overloaded circuits and conducting regular checks, can extend the life of your fuses and keep your systems running smoothly.