Schematic Kohler Engine Wiring Diagrams

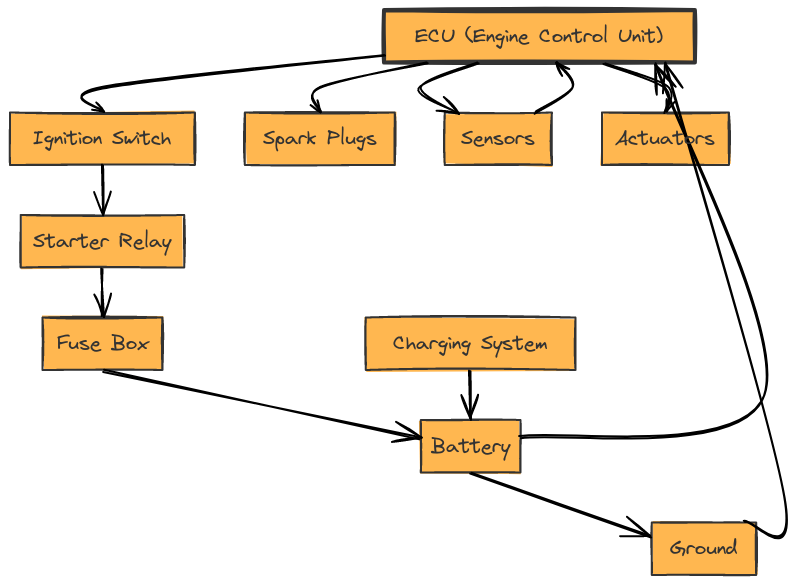

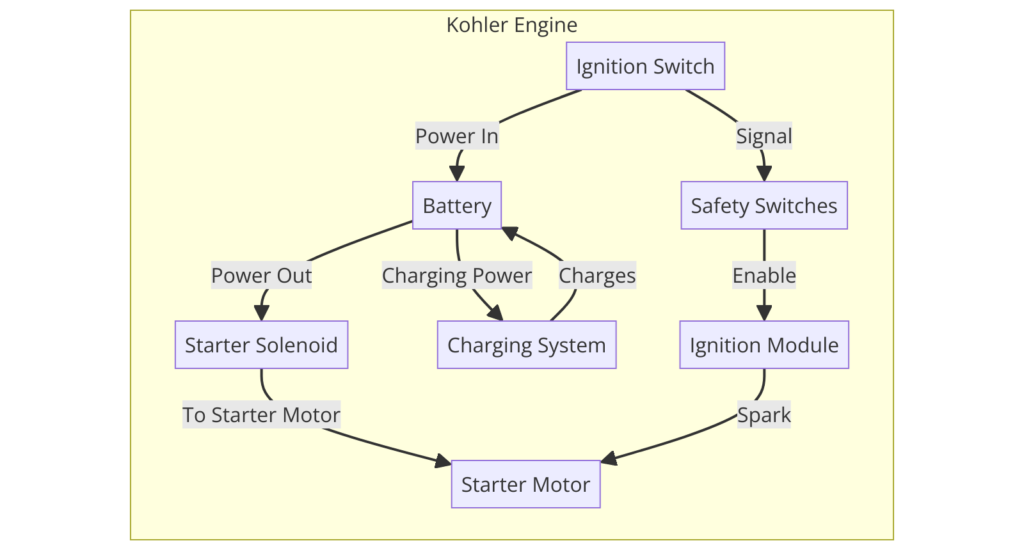

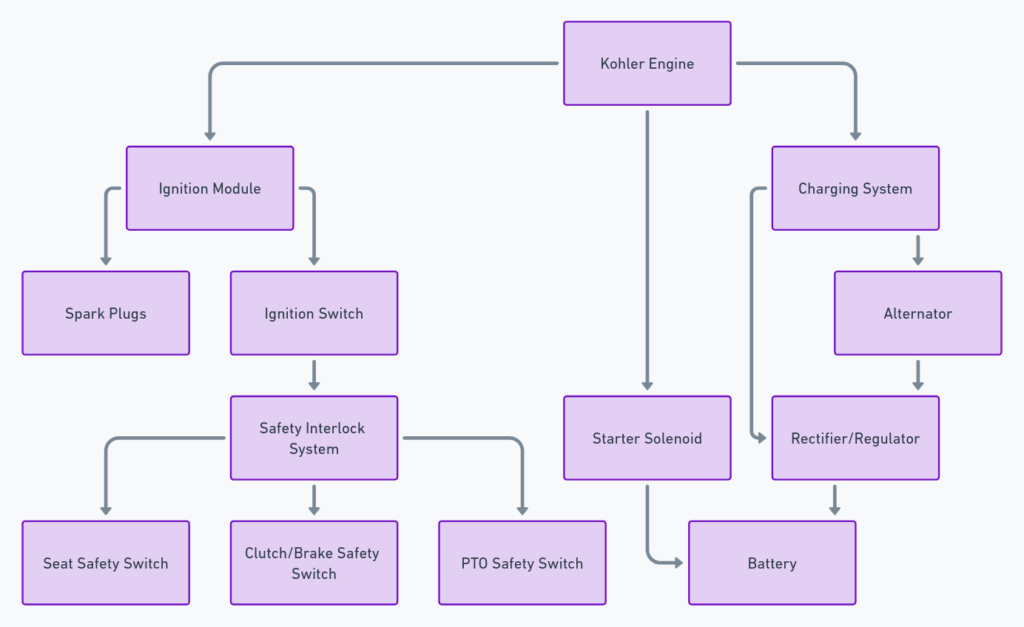

Kohler engines are known for their reliability and durability, powering a wide range of outdoor power equipment, from lawn mowers to generators. At the heart of these engines lies the electrical system, which is often represented through a schematic wiring diagram. These diagrams provide a detailed roadmap of the engine’s electrical components and their interconnections, helping technicians and DIY enthusiasts understand and troubleshoot any electrical issues.

Components Included in a Kohler Engine Wiring Diagram

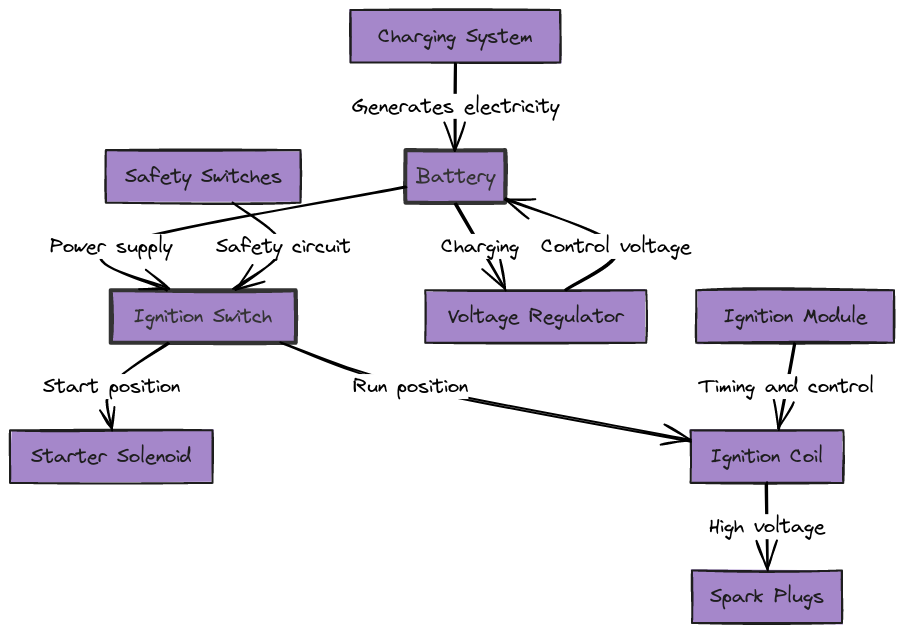

A typical Kohler engine wiring diagram may include the following components:

- Ignition system (spark plugs, ignition coil, ignition module)

- Charging system (alternator, voltage regulator)

- Battery and battery connections

- Starter motor and solenoid

- Safety switches (oil pressure switch, safety interlocks)

- Wiring harnesses and connectors

- Accessory components (fuel solenoid, hour meter, etc.)

Schematic Kohler Engine Wiring Diagrams

Diagram 1:

Diagram 2:

Diagram 3:

Diagram 4:

How to Read a Kohler Engine Wiring Diagram

Reading a Kohler engine wiring diagram may seem daunting at first, but with a little practice, it becomes a valuable tool for understanding and troubleshooting the electrical system. Here are some tips to help you navigate these diagrams:

- Identify the main components: Start by familiarizing yourself with the key electrical components of the engine, such as the ignition system, charging system, and starter.

- Follow the wire connections: Trace the wires from one component to another, noting how they connect and where they terminate.

- Understand color-coding: Kohler engine wiring diagrams often use color-coding to differentiate between various circuits and signal types.

- Locate ground points: Identify where the ground connections are made, as these are crucial for the proper functioning of the electrical system.

- Identify safety and control features: Pay attention to switches, relays, and other safety or control devices, as they play a vital role in the engine’s operation.

Troubleshooting Kohler Engine Electrical Issues

When troubleshooting electrical issues in a Kohler engine, the wiring diagram can be an invaluable resource. By understanding the diagram and the function of each component, you can methodically isolate the root cause of the problem and make the necessary repairs. Common electrical issues in Kohler engines may include:

- Battery charging problems

- Starter motor failure

- Ignition system misfiring

- Wiring harness damage or loose connections

By following the wiring diagram and testing individual components, you can quickly identify and address these issues, ensuring your Kohler engine continues to operate smoothly.

Conclusion

Schematic Kohler engine wiring diagrams provide a comprehensive overview of the electrical system, helping technicians and DIY enthusiasts understand the engine’s inner workings and troubleshoot any electrical problems. By familiarizing yourself with these diagrams and the components they represent, you can ensure your Kohler engine continues to perform reliably for years to come.