What is a Transformer? A Detailed Guide on Types and Uses

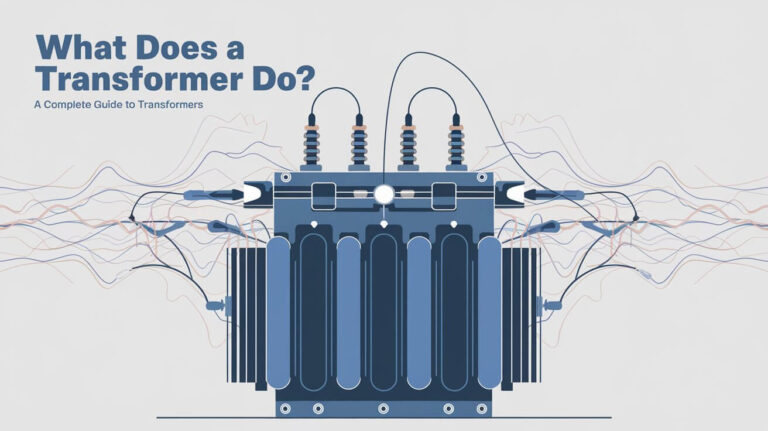

A transformer is a device used in electrical systems to transfer electrical energy between two or more circuits through electromagnetic induction. The primary function of a transformer is to alter voltage levels — either stepping up (increasing) or stepping down (decreasing) the voltage. It plays a crucial role in electrical transmission and distribution systems, allowing electricity to travel long distances efficiently.

How Does a Transformer Work?

Transformers operate based on the principle of electromagnetic induction, first discovered by Michael Faraday. When alternating current (AC) flows through a conductor, it creates a magnetic field. A transformer uses this phenomenon to transfer electrical energy between circuits without any physical connection between them. Here’s how it works:

Electromagnetic Induction Principle

At the core of a transformer’s operation is Faraday’s Law of Electromagnetic Induction. When alternating current passes through the primary coil (input), it generates a magnetic field that varies with the current. This varying magnetic field induces a voltage in the secondary coil (output). The ratio of voltages between the primary and secondary coils is determined by the number of turns (windings) in each coil. This relationship is given by the formula: V1/V2=N1/N2V_1 / V_2 = N_1 / N_2V1/V2=N1/N2

Where:

- V1V_1V1 and V2V_2V2 are the primary and secondary voltages, respectively.

- N1N_1N1 and N2N_2N2 are the number of turns in the primary and secondary windings.

Key Components of a Transformer

Every transformer has a few essential components that allow it to perform its function:

- Primary Coil: The input coil where the AC voltage is applied.

- Secondary Coil: The output coil that delivers the transformed voltage.

- Magnetic Core: Usually made of iron, this core helps in efficiently transferring the magnetic flux between the primary and secondary coils.

The magnetic core enhances the coupling of the magnetic field between the coils, ensuring minimal energy loss during the process.

Transformer Equations and Calculations

The performance of a transformer can be predicted using basic formulas. The most fundamental is the transformation ratio:V1/V2=N1/N2=I2/I1V_1 / V_2 = N_1 / N_2 = I_2 / I_1V1/V2=N1/N2=I2/I1

This equation shows the relationship between the voltages (V), the number of turns (N), and the currents (I) on both sides of the transformer. For example, a transformer with twice as many turns on the secondary coil as the primary will step up the voltage by a factor of two, but the current in the secondary will be half that in the primary.

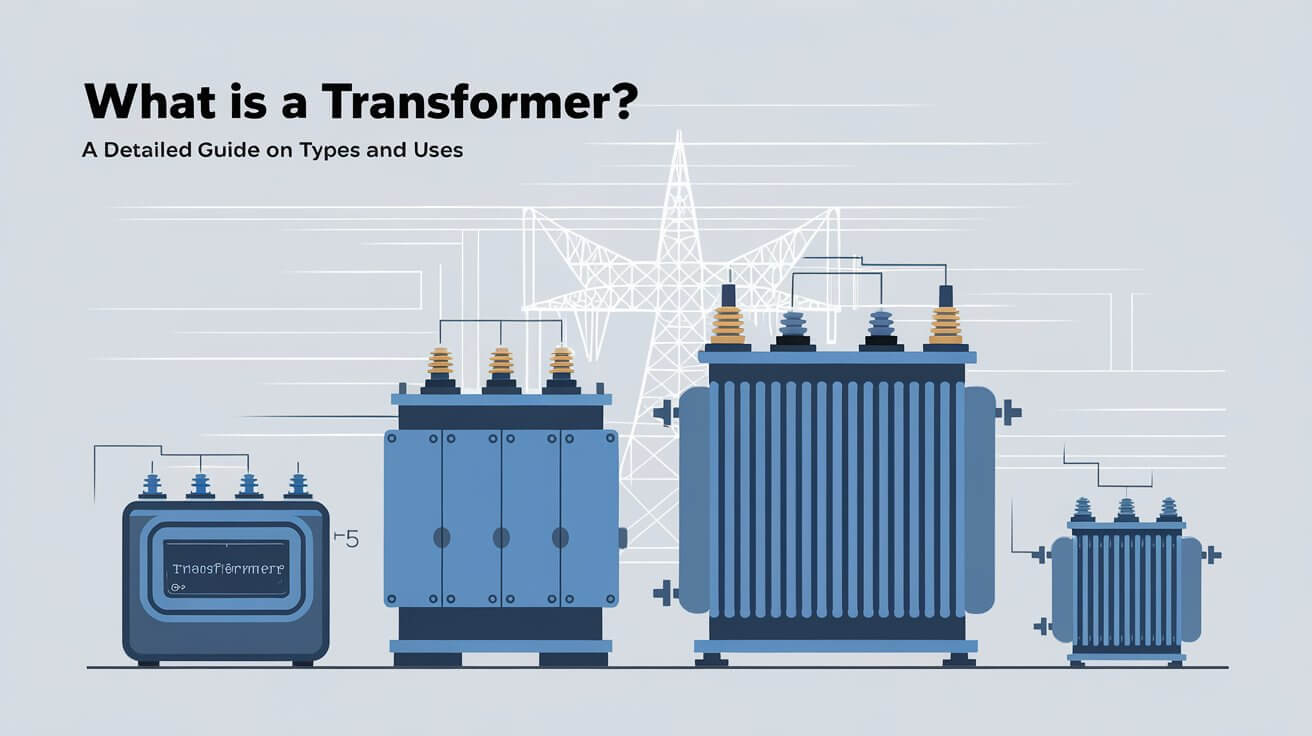

Types of Transformers

Transformers come in various types, depending on their application, voltage levels, and construction. Below are some of the most common types.

Based on Voltage Levels

Step-Up Transformer

A step-up transformer increases the voltage from the primary to the secondary winding. This type of transformer is essential in power plants, where low-voltage electricity generated by the plant needs to be transmitted over long distances at higher voltages to reduce energy losses.

Step-Down Transformer

A step-down transformer, conversely, reduces the voltage from the primary to the secondary winding. These transformers are found near homes and businesses, lowering the high transmission line voltages down to safer, usable levels for everyday applications.

Based on Core Type

Air-Core Transformer

In an air-core transformer, the magnetic flux between the primary and secondary windings occurs through the air. These transformers are generally used in radio-frequency applications where inductance is low and the efficiency of flux linkage is not as critical.

Iron-Core Transformer

Most transformers used in power systems are iron-core transformers. The primary and secondary windings are wrapped around a magnetic core made of iron or a similar material. This core provides a highly efficient path for magnetic flux, allowing for better coupling and higher efficiency.

Based on Function

Isolation Transformer

An isolation transformer separates two circuits electrically while still allowing power to transfer between them. This provides safety by preventing direct electrical connection between the primary and secondary windings, protecting sensitive equipment.

Autotransformer

Unlike traditional transformers with separate primary and secondary windings, an autotransformer has a single winding that acts as both the primary and secondary. It is more compact and efficient but does not provide electrical isolation between circuits.

Specialized Transformers

Instrument Transformers

Instrument transformers, such as current transformers (CTs) and potential transformers (PTs), are used in measurement and protection systems. They allow high voltages or currents to be measured safely at lower levels that are manageable by meters or protection relays.

Pulse Transformers

Pulse transformers are designed to transfer electrical pulses with minimal distortion. They are often used in digital logic circuits and high-speed data transmission.

Construction of Transformers

Understanding how transformers are built helps explain their efficiency and durability in different applications. Below are the key construction elements of transformers.

Magnetic Core Materials

The core is a critical part of a transformer, as it significantly impacts efficiency. The core materials are usually highly magnetic, like silicon steel, to minimize energy losses. Depending on the design, cores may be either core-type or shell-type constructions.

Types of Windings

The windings in transformers are made of copper or aluminum, materials with high electrical conductivity. Depending on the voltage and current, the number of turns and the thickness of the wire are adjusted to meet the requirements of the transformer’s application.

Insulation and Cooling Mechanisms

Transformers, particularly high-power ones, generate heat. Therefore, they require cooling mechanisms such as oil or air cooling. Oil-immersed transformers use a special insulating oil to cool the transformer, while dry-type transformers use air circulation to dissipate heat.

Applications of Transformers

Transformers are used in a wide range of applications, from power generation and transmission to small consumer electronics. Below are some of their most common uses.

Power Transmission and Distribution

In power systems, transformers are indispensable. Step-up transformers are used at power generation stations to increase voltage and allow electricity to be transmitted efficiently over long distances. Once the electricity reaches its destination, step-down transformers reduce the voltage to safer levels for distribution to homes and businesses.

Electronics and Consumer Devices

Small transformers are found in everyday electronics, from mobile chargers to televisions. These devices require different voltage levels, and transformers provide the necessary conversion.

Industrial Uses

Transformers are also used in industrial settings to power heavy machinery, motors, and equipment that require specific voltage levels. Power transformers, which can handle high voltages and large loads, are common in these environments.

Transformer Losses and Efficiency

Transformers are highly efficient devices, but they do experience some energy losses, particularly in the form of heat. These losses fall into two primary categories: core losses and copper losses.

Types of Losses

Core Losses (Hysteresis and Eddy Currents)

Core losses occur due to the continuous magnetization and demagnetization of the iron core as the current alternates. Hysteresis losses arise from the magnetic properties of the core material, while eddy current losses are caused by circulating currents induced within the core itself.

Copper Losses

Copper losses occur due to the resistance in the transformer windings. When current flows through the windings, some of the electrical energy is lost as heat due to the resistance of the material.

Methods to Minimize Losses

To minimize these losses, engineers use high-quality core materials like amorphous steel, which have lower hysteresis losses. In addition, better cooling systems and efficient winding techniques can significantly reduce energy loss.

Efficiency Metrics

Most transformers have efficiencies of between 95% to 99%, particularly large power transformers used in electrical grids. Smaller transformers, like those found in consumer electronics, may have slightly lower efficiency.

Transformer Protection and Maintenance

To ensure the longevity and reliable operation of transformers, regular protection and maintenance are critical.

Protection Mechanisms

Buchholz Relay

This relay is a gas-operated safety device used to detect faults in oil-filled transformers. If a fault occurs, gases are produced inside the transformer, and the Buchholz relay triggers an alarm to prevent further damage.

Surge Protection

Transformers are also equipped with surge protection devices that shield them from high voltage spikes caused by lightning or other external factors.

Regular Maintenance

Routine maintenance, such as oil testing and inspecting insulating materials, is essential for preventing breakdowns and extending the life of a transformer.

Evolution and Future of Transformers

Historical Development

The history of transformers dates back to the mid-19th century with the discovery of electromagnetic induction by Michael Faraday. Over the years, transformers have evolved significantly, from rudimentary designs to highly efficient devices used in modern power grids.

Smart Transformers

Looking ahead, smart transformers are becoming increasingly important in the context of smart grids and renewable energy. These advanced transformers can monitor and adjust voltage levels automatically, enhancing grid efficiency and reliability.

FAQs About Transformers

What is the Difference Between Step-Up and Step-Down Transformers?

A step-up transformer increases voltage, while a step-down transformer decreases it. Step-up transformers are used in power generation, and step-down transformers are used in power distribution.

How Does a Transformer Step Up or Step Down Voltage?

A transformer steps up or down voltage by adjusting the number of turns in its primary and secondary windings. More turns in the secondary coil increase voltage, while fewer turns reduce it.

Why Do Transformers Hum?

The humming sound from transformers is caused by the vibration of the core as it magnetizes and demagnetizes with the alternating current.

Can a Transformer Increase Power?

No, a transformer cannot increase power. It only alters the voltage and current, but the total power remains the same, minus any losses.

How Are Transformers Used in Renewable Energy?

Transformers in renewable energy systems,are critical for converting the output of wind turbines, solar panels, and other renewable energy sources to the appropriate voltage levels for grid integration. They help manage fluctuations in power supply from these variable energy sources and ensure efficient transmission to the grid.

Conclusion

Transformers are indispensable in modern electrical systems, serving a vital role in both power generation and distribution. Whether increasing voltage for long-distance transmission or decreasing it for local use, transformers ensure that electricity can be transmitted efficiently and safely. With ongoing innovations, especially in the realm of smart transformers and renewable energy integration, the future of transformer technology continues to evolve, promising greater efficiency and sustainability in electrical grids worldwide. Understanding how transformers work and their various types and applications can provide valuable insight into the broader electrical infrastructure that powers our daily lives.