Demystifying Transformer Wiring Diagrams: Full Visual Guide

Have you ever looked at a wiring diagram for a power transformer and felt completely lost? As an electrical engineer or technician, being able to interpret these complex schematics and connection diagrams is an essential skill. But where do you start?

What if you could easily determine a transformer’s specifications and capabilities just by examining its wiring diagram?

The goal of this guide is to provide a step-by-step visual walkthrough for reading transformer wiring diagrams. You’ll learn how to identify key components, understand primary and secondary windings, and interpret manufacturer schematics.

Specifically, we’ll cover:

- The purpose and format of transformer wiring diagrams

- How to read a transformer nameplate

- Differences between single-phase and three-phase units

- The role of tap changers and auxiliary devices

- Interpreting manufacturer diagrams and drawings

- Real-world applications for installing and troubleshooting transformers

Follow along, and you’ll gain the knowledge to effectively utilize these critical diagrams on your next electrical project.

Transformer Wiring Diagrams

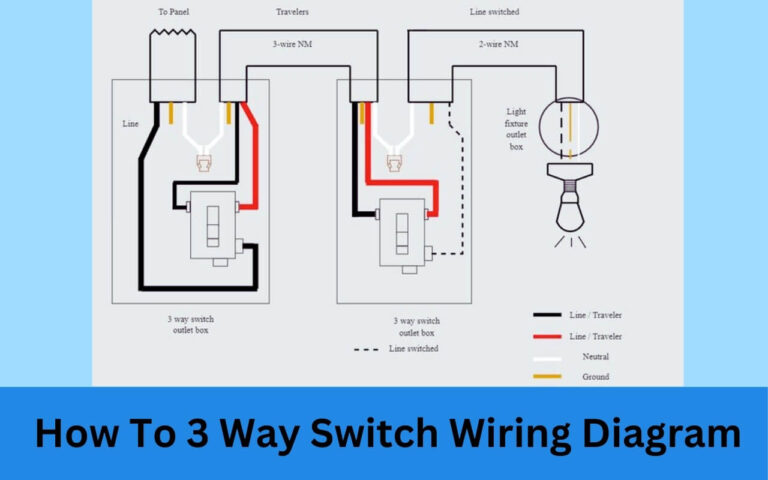

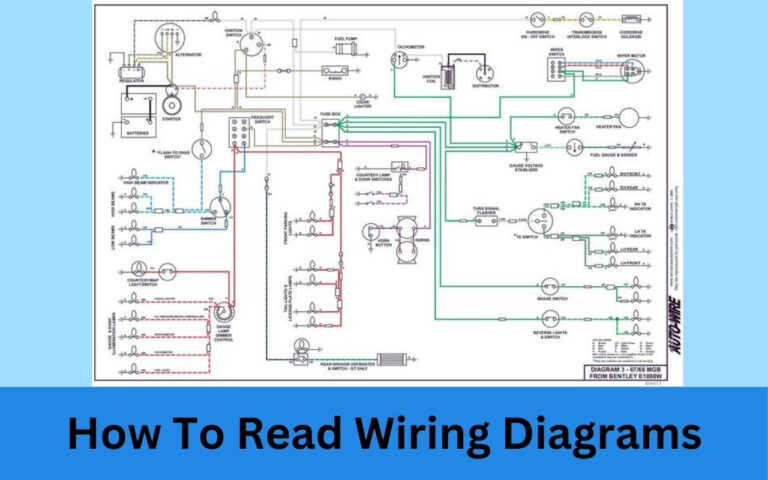

Diagram 1

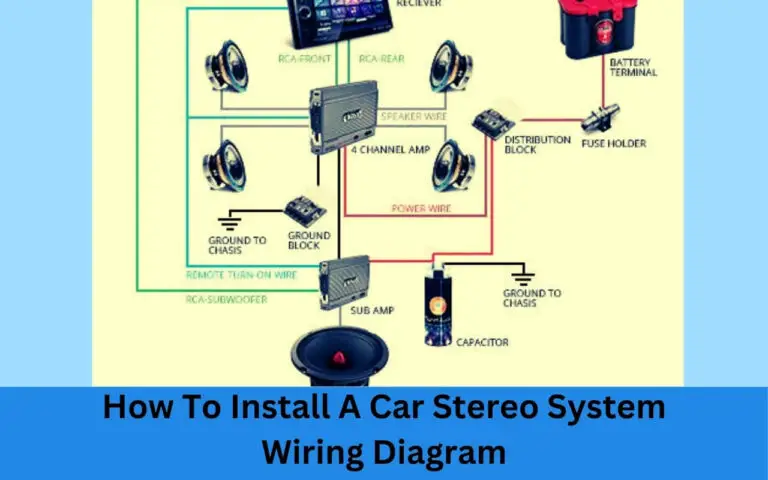

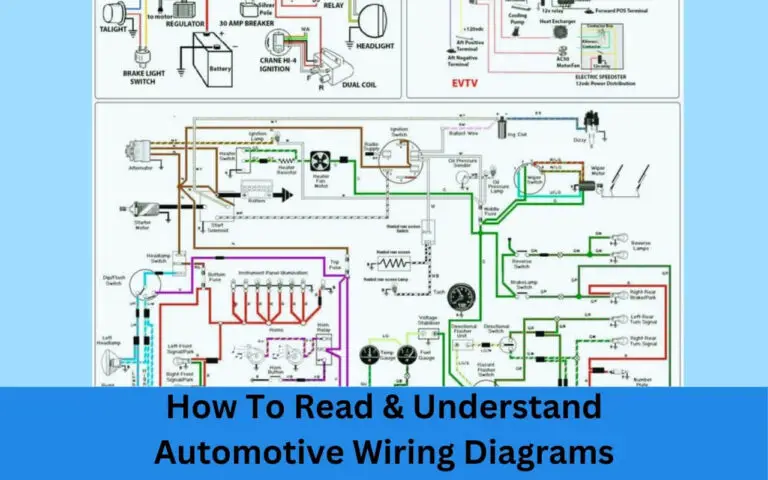

Diagram 2

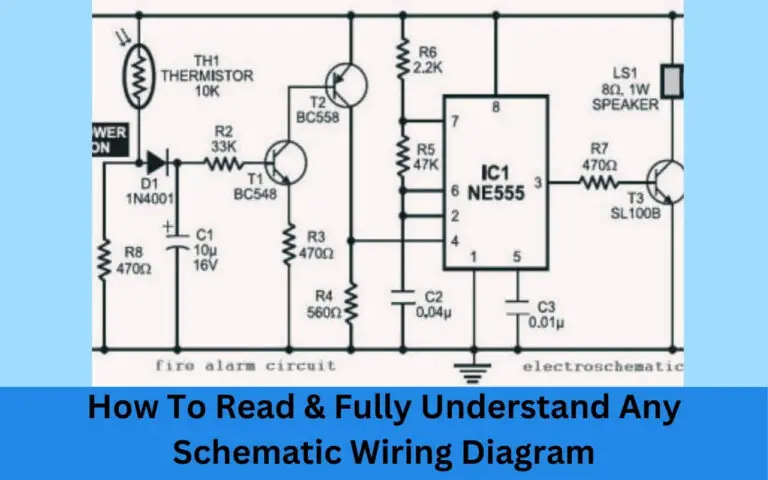

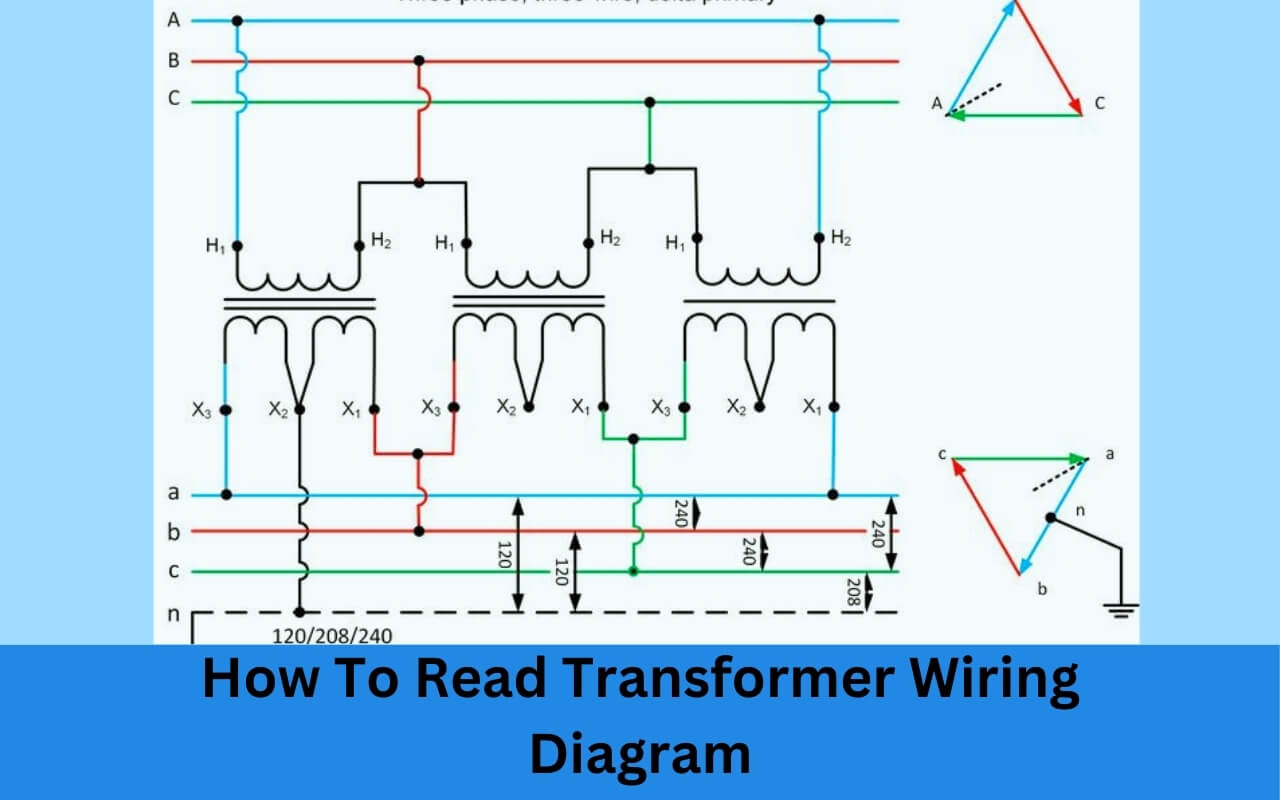

Diagram 3

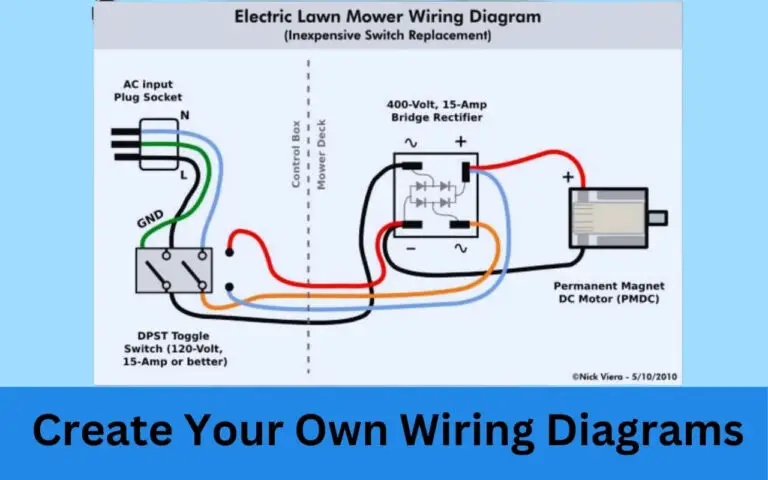

Diagram 4

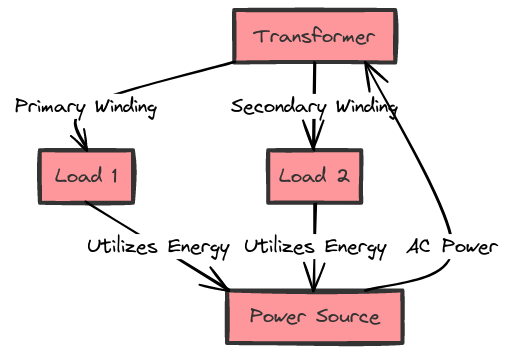

A Wiring Diagram Represents Connections, Not Physical Layouts

A wiring diagram uses symbolic and schematic drawings to depict interconnections and relationships within an electrical device or circuit.

In contrast to physical layout diagrams, wiring representations are intended to convey the logical connections and functions rather than exact locations.

For power transformers, these simplified schematics allow technicians to recognize functional units, isolate malfunctions, and select replacement parts. Portable document format (PDF) drawings are commonly provided by manufacturers.

Wiring diagrams utilize standardized symbols and iconography. Familiarity with the designated representations for individual components is key for accurate interpretation.

Begin With the Transformer Nameplate

The best place to start when deciphering any new wiring schematic is examining the transformer nameplate. Think of this label as the transformer’s ID tag.

On power units, the nameplate is a metallic plate located on the outside of the tank near the bushings. Key specifications like serial number, manufacturer, power rating, tapped windings, and impedance are stamped directly on the plate.

Additional reference designations may be marked elsewhere on the tank exterior. However, the nameplate should always be checked first when considering a replacement transformer.

Information typically noted includes:

- Manufacturer and place of assembly

- Product or catalog number

- Serial number and date of initial service

- Frequency rating in hertz (Hz)

- Single or three-phase (1Ø or 3Ø) configuration

- Available tap positions by percentage

- Cooling method such as OA (oil and air)

- Impedance percentage and base values

- Weight and total insulating fluid volume

Recording this reference data before examining the wiring diagram allows for easier validation ofWinding connections and verifying specs.

Single-Phase Units Have One Primary & One Secondary

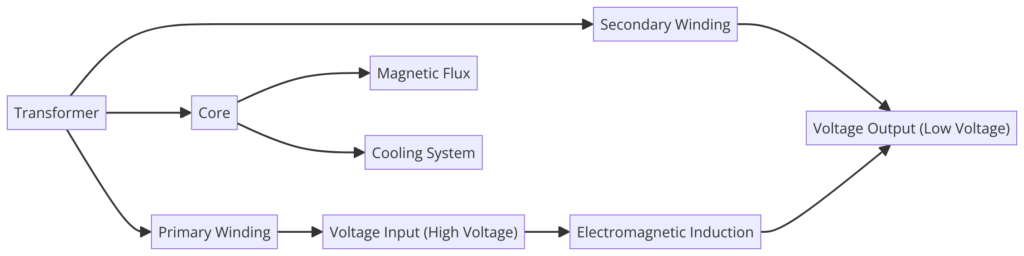

Power transformers utilizeinduction to convert electric energy at one voltage to another level. This transformation occurs between the coils of the primary and secondary windings.

Single-phase transformers containone winding per side. The source connects to the primary side which often has multiple tap positions to adjust output levels. The load connects to the secondary.

On single-phase diagrams,the primary leads are typically labeled H1, H2 (High Voltage) while the secondaries are X1, X2 (eXciter). Phase shift between sides depends on polarity markings.

Three-phase transformers have three interconnected windingsper side, and thus additional connections. They utilize rotating magnetic fields for power transfer.

Three-Phase Units Have 3 Windings Per Side

As the name indicates,three-phase power transformers have three windings each on their primary and secondary sides. Each winding carries current 120 degrees out of phase from the others.

Together, the three windingsenable balanced three-phase voltage networks. This arrangement also enables versatility in winding connections.

The graphics above show the commondelta (Δ) and wye (Y) connections. Leads for the three coils on each side are brought out to external bushings or terminals.

Three-phase transformers may specifyif the high voltage or low voltage sides utilize wye or delta arrangement. So a Δ-Y unit has a delta primary and wye secondary.

Phasor diagrams represent phase shift implications between sides.

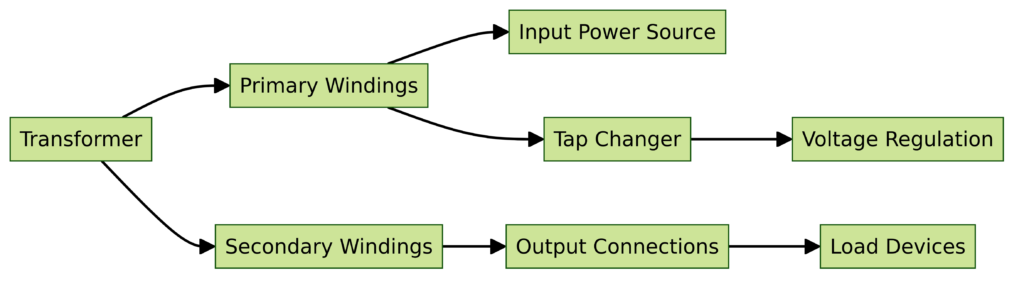

Tap Changers Modify Output Voltage

To regulate transformer output voltageswithin a narrow range, tap changers provide multiple connection points along the windings.

When enabled, tapping alters the turns ratio between the primary and secondary sides. This allows the operator to accommodate small grid fluctuations.

For three-phase units, tap changingoccurssimultaneously across all three secondaries. Control and activation of motorized changers occurs externally, often via voltage sensors.

Wiring diagrams indicate the number of available taps and voltage step increments between positions. 5 to 25 ratios are common.

Cooling Mechanisms Aid Heat Dissipation

As transformers operate, both ironand copper losses generate substantial waste heat. If left unchecked, excessive temperatures can damage internal components.

Various cooling methods help maintainefficient operating conditions and extend service lifetimes. Passive mechanisms like radiators and cooling fins leverage natural convection.

Forced-oil and directed airflowsystems utilize pumps and fans for active cooling. Wiring diagrams may show connections for these auxiliary devices.

Understanding the transformer’s thermal constraints aids in assessing acceptable load capacities for your electrical network.

Manufacturers Provide Secondary Connections

In addition to the transformer itself,wiring diagrams depict multiple external connections for utilized components.

Manufacturers often pre-bundle certain devices like fuses, surge arrestors, voltage transformers (VT), and grounding cables. These ship pre-wired to streamline installation.

Wiring diagrams indicate where technicians must land cables for source feeders and outgoing circuitry. They also specify additional devices like control power transformers (CPT) used in sensing and regulation.

Thoroughly examining the manufacturer’s drawings reduces surprises and ensures your selected transformer fits the intended application.

Interpreting Multiple Similar Units

For large sites with multiple step-downtransformers, the wiring diagrams facilitate identifying key distinctions between units.

Even transformers with identical voltage and power ratings may vary in their configurations and capabilities based on intended service environments.

Always cross-reference markings on physical equipment with the drawings…inconsistencies could indicate an outdated schematic.

Watch for subtle details like separate auxiliary transformer voltages and alternative tapping ranges. These fine differences influence transformer selection and placement on your electrical grid.

Real-World Applications and Uses

Now that we’ve covered the key elements of deciphering power transformer wiring diagrams, we should briefly highlight some practical applications.

Familiarity with interpreting these technical drawings lends itself to a variety of functions:

Procurement & Specification

Correctly reading diagrams enables proper selection and sizing of replacement units.

Installation & Commissioning

Following provided diagrams ensures correct electrical connections during field assembly.

Inspection & Maintenance

Routine checks verify that wiring matches diagrams to identify modifications or damage.

Troubleshooting & Repair

Isolating faults requires understanding intended component arrangements.

Simply put, correctly leveraging these diagrams directly enables safer and more reliable power systems.

Key Takeaways from Our Visual Guide

- Wiring diagrams use symbols to convey logical electrical connections

- The nameplate provides key specifications for a given transformer

- Single-phase units have one primary and one secondary winding

- Three-phase configurations have three windings per side

- Tap changers enable operators to regulate output voltage

- Cooling mechanisms aid heat dissipation during operation

- Manufacturers often provide pre-wired secondary connections

- Compare similar transformers to identify subtle configuration differences

- Comprehending diagrams has many practical field applications

With these fundamentals, you now have the knowledge to take your interpretation of transformer wiring diagrams to the next level.

As you examine various schematics, pay attention to the subtle nuances that make each unit unique. Understanding these fine details helps ensure you select and integrate transformers properly into your electrical infrastructure.

Still have questions? Reach out in the comments below!